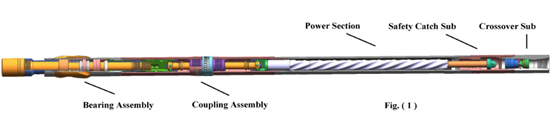

Downhole motors differ in size and performance characteristics, but they share the same basic components as follows (Fig.1) :

·Crossover Sub

·Safety Catch Sub

·Power Section

·Coupling Assembly

·Bearing Assembly

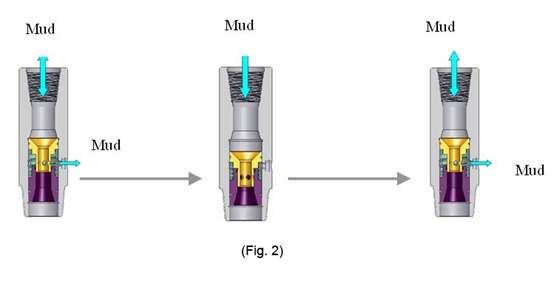

CROSSOVER SUB

Bobby crossover sub (Fig. 2) provides two functions. Its primary use, serves as a crossover between the motor assembly and the drill stem. It also allows for placement of a float valve.

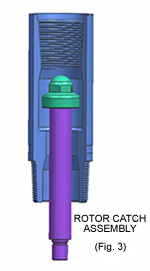

SAFTY CATCH SUB

This is a safety feature that is incorporated into the design of all Bobby motors. It serves as a retaining device in the event of an external connection failure in the motor (Fig. 3)

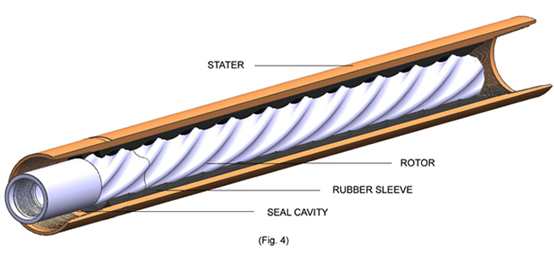

POWER SECTION

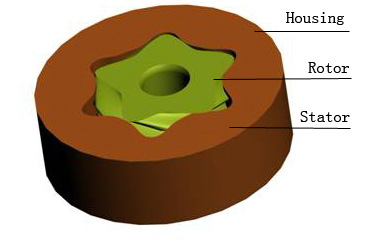

It consists of stator and rotor. Stator is made by squeezing rubber sleeve on the wall of steel tube, the rubber sleeve inside forms spiral structure with a certain geometric parameter . Rotor is a crome-plated steel shaft with a helical profile, which runs inside the stator (Fig. 4).

Drilling fluid is pumped downhole through the drill pipe at a given rate and pressure. Once the hydraulic energy of the drilling fluid reaches the motor, that fluid moving through the power section is converted into rotation and torque. This mechanical energy is transferred through the rest of the motor directly to the drill bit.

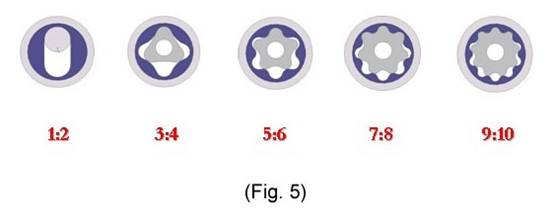

The power section has many different configurations available. These configurations vary on basis of torque and rpm(rate per meter) requirements, as well as downhole conditions such as temperature and drilling fluids used. helical line on rotor is divided into single end and multi-end ( stator with one more end than rotor). (Fig. 5)

The stator as below:

Hollow Rotor Motor - To increase hydraulic horsepower and upward speed of drilling fluid, rotor is manufactured into hollow rotor with nozzles.

COUPLING ASSEMBLY

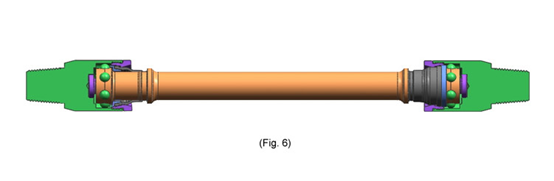

The flexible coupling is the link between the rotor and the bearing mandrel. This assembly is to convert rotary motion of the power section into fixed constant rotation of drive shaft, to transmit torque and speed from power section on the drive shaft, and to the drill bit (Fig. 6).

The coupling assembly also has many different configurations available:

·Ball drive universal shaft

·Flat universal shaft

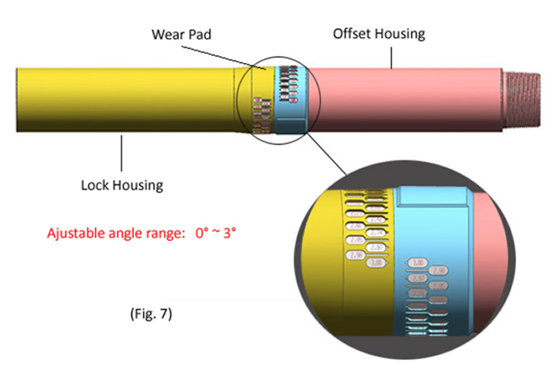

NYJ has the ability of manufacturing Adjustable Bend Housing. The bend angle adjustment range from 0°to 2°、0°to 3° (Fig. 7).

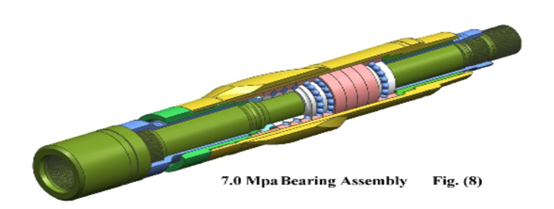

BEARING ASSEMBLY

The bearing assembly is designed to transmit the mechanical energy onto the bit, meanwhile to withstand the thrust and radial loading applied to the motor during operation.

The thrust loads can come from various sources, such as weight applied to the motor, hydraulic pressure drops across the drill bit and/or power section, and back-reaming operations.

We have two types of drive shafts, as follows (Fig. 8):

·Bit pressure drop is 7.0 Mpa, the drive shaft assembly with hard alloy radial bearing and thrust bearings in the middle part.

·Bit pressure drop is 14.0 Mpa, the drive shaft assembly with hard alloy radial bearing and PDC cutter flat thrust bearing. It has longer life and higher performance.

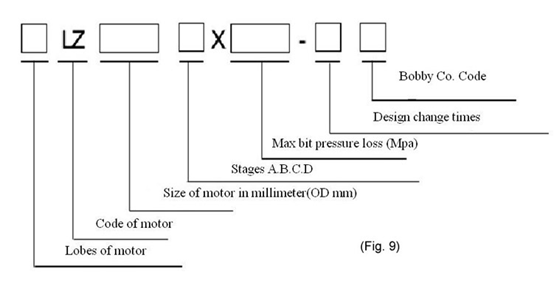

DOWNHOLE MOTOR MODEL

Контакты: Maya

Мобилльный Тел.: 13584111028

Почта: maya@nyjdrillingmotor.com

Whatsapp:86-13584111028

Адрес компании: No.8 Jingyi Rd, Industrial Park, Dagang town, Yandu District, Yancheng -224043, Jiangsu, China

We chat